Complaint Review: DuraSystems Barriers Inc. - Vaughan Ontario

- DuraSystems Barriers Inc. 199 Courtland Avenue Vaughan, Ontario Canada

- Phone: 905-660-8887

- Web: http://www.durasystems.com/

- Category: Utility Companies, electric utilities, Electrical Services

DuraSystems Barriers Inc. DSBI DuraBarrier high-voltage transformer fire barrier is a scam. All 16 test reports in test index 34, Table 1.2.2 are bogus. Vaughan Ontario

*Author of original report: Private sector takes civil actions against John P. Sinisi and DuraSystems Barriers Inc. (DSBI).

listed on other sites?

Those sites steal

Ripoff Report's

content.

We can get those

removed for you!

Find out more here.

Ripoff Report

willing to make a

commitment to

customer satisfaction

Click here now..

Do you pay for your electricity directly or through your rent? This (“DuraBarrier” a wittingly misrepresented, Canadian/British critical infrastructure protection product, used to stop burning/exploding high-voltage transformers from taking down neighbouring transformers, which can cause a domino effect and affect the surrounding grid by causing a brown-out or cascading failure. “DuraBarrier”, an inoperable high-voltage transformer fire barrier, is made by DuraSystems Barriers Inc. – DSBI, of Vaughan, Ontario, Canada, durasystems.com, imported into the US through a cut-out: sinisisolutions.com) may have ripped you off indirectly, and many North American utilities directly, who passed the cost of the DuraBarrier scam (fraud financial damages, not considering a fire or ballistic event failure, include the costs for substation shut-down, invoice from DSBI, invoice from sinisisolutions.com, invoice from a local installer plus an invoice from a locally licensed engineer - for local seismic and wind load vetting) on to everyone who buys electricity from the scammed utility, of which there are many, both in the US and Canada, plus it has weakened the electric grid (wittingly imperilling Critical National Infrastructure) by causing utilities to rely on a product based on rigged and failed testing, mentioned in DSBI’s test index 34, Page 6, Table 1.2.2 – 16 bogus tests that would have a fire test engineer rolling on the floor laughing. If DuraBarrier is allowed, why bother to stop foreign hackers from taking down the electric grid? This post describes the test fallacies, concealed from utilities by blatantly false advertising.

Critical Infrastructure Protection for the electric grid is a matter of national security – but it is also a pocketbook issue for hydro ratepayers. “DuraBarrier” has been installed in many North American substations, probably since at least 2006, the date of the bogus A40 test in table 1.2.2 of DSBI’s test index 34. The topic, in general, not DuraBarrier or any of its rival products in particular, is described here:

en.wikipedia.org/wiki/High-voltage_transformer_fire_barriers

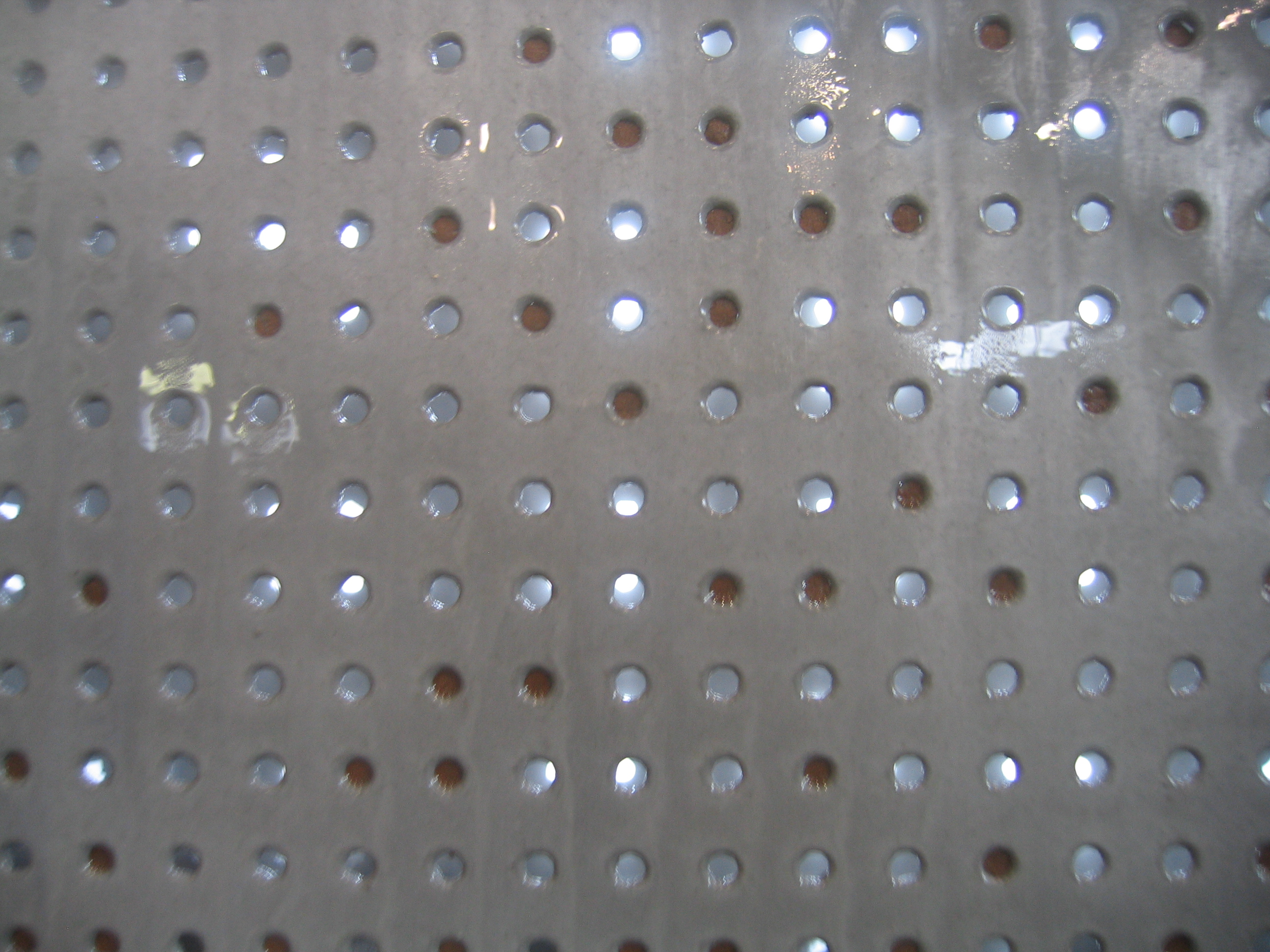

The problem is that outdoor substations with large electrical transformers are not buildings. Therefore, no building code or fire code applies, which means there is no Authority Having Jurisdiction (AHJ). No AHJ would allow “DuraBarrier” in a building because it fails to meet the conditions of acceptance of fire test standard ASTM E119 (.astm.org/Standards/E119.htm), which is a precondition to meeting NFPA 850 (nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=850) Recommended Practice for transformer fire walls in substations. If it did meet the recommendations in NFPA 850, which it does not, it could also be used in a building. There is no functional 2-hour, let alone 6-hour fire barrier at 3/8” or 9.5mm thickness. Humankind does not currently possess such technology. DuraBarrier is a single, naked sheet of British-made Durasteel, at 3/8” or 9.5mm thick, fastened to a steel frame. The 16 test reports in Table 1.2.2 of DSBI test index 34, used to misrepresent DuraBarrier are all either rigged or failed in one way or another. DuraBarrier is ineligible for UL certification listings because it does not conform to the ASTM E119 conditions of acceptance. Durasteel, made by Promat UK in England, and formerly by Cape Durasteel Ltd., the only proprietary component in DuraBarrier (fabricated in Canada by DSBI), is UL listed and works for use in other applications, but not “DuraBarrier. The only way utilities are bamboozled into buying into this scam is because the decision makers have electrical backgrounds – not fire-resistance knowledge, which is an architectural discipline, which is not consulted in matters concerning outdoor electrical substations.

Sinisisolutions.com, the US cut-out, without evidence, goes further in its claims than DSBI, including stating that the product is made in USA, and capable of Jetfire testing, which is a very severe, large flamethrower test, that DuraBarrier has not been tested to.

This is a multi-million-dollar scam that has been running for years and appears to still be up and running.

This post describes fallacies inside of 16 test reports cited by DSBI in its test index 34, table 1.2.2., starting with the worst one: A40.

DSBI claims that it has 6 hours fire resistance (which sounds impressive without knowing the facts), tested to the ASTM E119 time/temperature curve. This is a deception. “Fire resistance”, in North America, for a non-loadbearing wall, means that it meets the conditions of acceptance of ASTM E119, which is identical to NFPA 251, CAN/ULC-S101 and UL 263. These 4 test standards are virtually the same and represent the state of the art in North America. DuraBarrier does not meet those conditions, not even close. But, contrary to Canada’s Competition Act, Section VII.1, Deceptive Marketing Practices (laws-lois.justice.gc.ca/PDF/C-34.pdf) and 15 U.S. Code Paragraph 45 (law.cornell.edu/uscode/text/15/45), DSBI, together with sinisisolutions.com makes a series of false claims, proven false by the actual test report. See some of the claims at a recent trade show right here: commons.wikimedia.org/wiki/Category:DuraBarrier_Exhibition_at_NFPA_Las_Vegas_Trade_Show,_June_2018. The egregiously deceptive 6-hour fire resistance claim is based on its “A40” test, mentioned in its test index 34, but also going back to earlier versions, such as test index 29, table 1.2.2. The test laboratory is the “Blackburn Fire Test Centre” (BFTC), falsely portrayed, with the assistance of Promat UK (owners of BFTC), as an independent test laboratory. BFTC, recently sold off to Exova, a proper fire test company, was an in-house lab, owned and operated by, and out of premises owned by Promat UK, with the same address, phone and fax number, in England. DuraBarrier is nothing other than an asymmetrical wall (which actually means it must be tested from both sides – it wasn’t), which is shown on the Wikimedia Commons Category “Asymmetrical fire barriers” (commons.wikimedia.org/wiki/Category:Asymmetrical_fire_barriers), made of a steel framework, without any fireproofing to keep the steel temperature from exceeding 1000 degrees Fahrenheit or 538 degrees Celsius heat rise above ambient at the beginning of the test (a requirement for structural steel in North American fire test standards), and then Durasteel panelling, (commons.wikimedia.org/wiki/Category:Durasteel), 3/8 inch or 9.5mm thick, made of low density and wood fibre re-enforced concrete, sandwiched in with perforated galvanised sheet metal – screwed into the steel frame with sheet metal screws. Identically to the Thermo-Lag Scandal (en.wikipedia.org/wiki/Gerald_W._Brown#Thermo-Lag_scandal), the manufacturer’s (Promat UK’s BFTC in-house lab) laboratory was used to qualify the product. As you can imagine, when the manufacturer tests his own products, it is possible that he gets great results. Also see nrc.gov/reading-rm/doc-collections/gen-comm/gen-letters/1992/gl92008.html. But it does not stop there. The test sample size was 8.9 square metres or 96 square feet – below the minimum required size, meaning the test was irrelevant on that basis alone. The reason for this smaller size is because the restraint frame that holds the test sample was narrowed in by what looks like pieces of precast concrete, thus resulting in the sample size below BOTH British AND North American Requirements. A40’s 8.9 square metre wall test sample size is solidly below the minimum size dictated by all 4 North American test standards (ASTM E119, CAN/ULC-S101, NFPA 251 and UL 263), as well as the British Standard BS476, from which most of the acceptance criteria was copied and pasted verbatim, whilst mentioning only ASTM E119. BS476 requires a minimum test sample size of 9 square metres, meaning the A40 test complies neither with ASTM E119 nor BS476. Each of the four North American standards require a minimum sample size of 100 square feet or 9.3 square metres. The A40 test falls short of this (meaning the whole test is bogus because of the sample size alone), but conceals the fact by not counting up the sample module sizes, which is also a requirement of the standards in terms of items required to be covered by test reports. The A40 test was done on one side only (despite the requirement in all North American test standards AND BS 476 to test both sides of asymmetrical wall test samples) because DSBI and BFTC (AKA Promat UK) claim that with the steel framework in the fire, they tested the most critical side, which is good enough – for them. That is a purposeful deception aided and abetted by Promat UK, who know better. The standards indicate that one must test two identical samples, one from each side. The results from both tests must be reported, which means, in practice, that whichever side gets the lowest fire resistance test result, that is the overall rating of the wall system. Test sponsor and manufacturer-owned test labs, do not get to pick which side is more dangerous and then save money (typically about US$20,000 per full size wall test in North American laboratories) by testing only one side whilst claiming to be in compliance with standards that say the opposite. By comparison, all drywall shaftwalls are asymmetrical and get tested on both sides. In practical use, one cannot know with certainty, which side the fire will come from. That is why the caution. It gets worse. DuraBarrier, meaning single sheets of Durasteel, fastened onto a steel frame that gets red-hot during a fire, meaning significantly lower strength than at ambient, are supposed to be suspended from concrete filled rectangular steel tubes, or HSS (Hollow Steel Section) columns. Such steel columns can work in fires, but they also exhibit fire behaviour whose effect upon DuraBarrier was never tested, and these columns are an integral part of the DuraBarrier wall system. Not including the full system that gets installed in the field contravenes paragraph 5 of ASTM E119, which states that test samples must match the field-installed configurations. So, the supports for DuraBarrier, that carry its load, were not tested together with DuraBarrier, contrary to paragraph 5 of ASTM E119. The steel frame of DuraBarrier gets red-hot in a fire. Authors of the A40 test report, including one J. Adams, same name as a Promat UK employee, listed as an application support manager, cherry-picks its own conditions of acceptance, taking the time/temperature curve to run the furnace with and the rest of the acceptance criteria verbatim from BS 476, a British standard, which has no validity whatsoever in North America, which is not mentioned in NFPA 850 either – a fact clearly known to DSBI, who claim expert status for themselves in matters of fire protection. One cannot comply with NFPA 850 recommendations by using a foreign fire test standard that it does not mention. Also, all single sheet Durasteel wall tests fail the temperature transmission requirements within approximately one quarter of an hour, from 10 to 21 minutes, in all furnace fire tests mentioned in table 1.2.2 in DSBI’s test index.

It gets worse yet.

The furnace is supposed to be calibrated and instrumented with furnace-interior thermocouples shielded inside of Inconel tubes. That’s called “shielded thermocouples”. Europeans use “fast response thermocouples”, with bare copper plates. The A40 test shows zero evidence that shielded thermocouples were used during the A40 test. Why does this matter? Because it can take 20 minutes or so for the thermocouples inside the Inconel tubes to accurately measure the furnace temperature, meaning that North American furnaces run hotter than European ones or anybody’s furnace run by means of fast response thermocouples early in the test, thus delivering a greater thermal shock at the beginning of the test. This fact was highlighted and quantified by the government of Canada: nparc.nrc-cnrc.gc.ca/eng/view/accepted/?id=f74c3459-d0dc-4349-a6d3-bdc1e80ae5f5. That means a slower, gentler thermal shock for test samples in furnaces equipped with fast response thermocouples – sort of like taking a grade 8 junior high school test in the third year of university – a wee bit easier. In the very similar Thermo-Lag Scandal, the United States Government had the manufacturer’s test furnace, which was used to qualify that same manufacturer’s product (Thermo-lag 330-1) disassembled and then re-assembled in Elmendorf, Texas, at Omega Point Laboratories (now Intertek), who conducted studies on behalf of the USNRC concerning fraudulently misrepresented electrical fireproofing (used to keep cables between control room and reactor inside of a nuclear power plant operational, in order to enable safe shutdown in the event of an emergency, involving an accidental fire). It’s a good idea to be able to switch off the reactor in a fire, same as it’s a good idea to keep burning and exploding transformers from having a domino effect… The studies provided with taxpayer funding by Omega Point Laboratories, now held at the Library of Congress, indicated that the Thermo-lag 330-1 fireproofing worked as intended when the furnace was equipped with fast response thermocouples – the furnace instrumentation was actually the “cheat” by Thermal Science Inc., the manufacturer of Thermo-lag 330-1. As soon as the same configuration of Thermo-lag fireproofed wiring was tested in a furnace equipped with shielded thermocouples, which is the requirement, it failed well before the claimed fire resistance rating period. This lacking performance was found out by nuclear whistle blower Gerald W. Brown (en.wikipedia.org/wiki/Gerald_W._Brown), who, at the time, was a principal in the Chemtrol company, which was a maker and installer of silicone foam through-penetration firestops (en.wikipedia.org/wiki/Firestop) in American nuclear power stations licensed by the USNRC. Gerald W. Brown had test reports to cover cable tray through-penetrations, firestopped with silicone foam, behind ceramic fibre form boards. What he lacked at the time, was evidence that when the wiring was fireproofed with Thermo-lag 330-1, there were no issues with his firestops and the direct contact between his firestop foam and the cable fireproofing. The fire test failed, at the location of the Thermo-lag 330-1 fireproofing, long before the expected time, causing Gerald W. Brown to report the matter to the USNRC, which set off a series of government run tests (funded by taxpayer funds), as well as litigation, followed by remedial action by USNRC license holders to protect their safe-shutdown trains (which ratepayers funded). So, the same test inconsistency that led to massive costs and litigation previously, which is public domain knowledge since the nineties, may have been in play in DSBI’s A40 test, as it offers no evidence whatsoever that the furnace was instrumented with shielded thermocouples, which is a North American requirement, without which, it is deceptive to use the defined term “fire resistance”, a fact well known to DSBI who claim expert status in the field. Also, the A40 test includes no hose stream, which is a water cannon test, at 3.1 bar or 45 PSI for several minutes, within 10 minutes of the end of the fire endurance test. Water must not project through the test sample to the unexposed side. The A40 test omitted this – one of many fallacies, that make it false advertising to use the defined term “fire resistance” in connection with DuraBarrier. Also, Promat UK’s conspiracy to commit fraud is apparent here. BFTC is not identified as being an in-house lab (with a stake in a positive outcome) in the test report. In fact, there is no mention of the conflict of interest in using a manufacturer’s in-house test as a means of demonstrating fitness for purpose – in the Colonies. Promat UK, indicatively, makes no mention of this A40 test in its own promotional literature – despite the otherwise impressive sounding (false advertising) 6 hours of fire-resistance, at a thickness of only 3/8” or 9.5mm. Also, BFTC, the Promat UK in-house test lab, did maintain UKAS accreditation. Again, indicatively, the A40 report states that this was an ad hoc test and, as such, outside of its accreditation scheme. Therefore, the accreditation is mentioned in order to highlight the quality of the in-house laboratory, but this test is not covered. It is entirely possible that this enabled Promat UK to conceal the A40 report from routine BFTC audit by UKAS, which may have resulted in notification to the Competition and Markets Authority (en.wikipedia.org/wiki/Competition_and_Markets_Authority) in London, once the effect of exporting under unfair auspices were understood. It is also not clear, whether the BFTC lab was accredited by UKAS to run ASTM E119 tests, which would have entailed checking for the use of shielded thermocouples, without which, the test has no validity for North America and represents an unfair trade practice whilst trading in or with North America. In the Thermo-Lag scandal, USNRC noted that when Thermal Science Inc (TSI) represented the ITL laboratory, which had done qualifying tests on Thermo-Lag electrical fireproofing, as an independent test laboratory, that this was a Severity 1 violation, which, in itself, was worth a civil fine of $100,000.00. BFTC was owned and operated by Promat UK, makers of Durasteel and providers of Durasteel to DSBI.

Test A1 through A21, in table 1.2.2 of DSBI test index 29-34, page 6, are all British BS476 fire tests with fast response furnace thermocouples, with the test sample Durasteel walls less than the North American minimum wall sample size of 100 square feet or 9.3 square metres. All failed the thermal transmission mandatory ASTM E119 requirement within 10-21 minutes. No hose stream was run. The earliest of these tests was in 1976, thus proving conclusively that DSBI, which began operations in 1990, knew, since its very inception, that a single sheet, uninsulated Durasteel wall does not meet minimum North American requirements. Also, any claim DSBI may represent to having, concerning proprietary intellectual property or copyright is disabled on account of the fact that the earliest tests of single sheet Durasteel walls resemble DuraBarrier. Using somewhat different steel profile configurations to make the frames to screw the Durasteel panels into, is no great scientific leap. Further, similar systems are also promoted by rival Invicta, another Promat UK distributor, who, just like DSBI, posts pictures of such single sheet barriers, fashioned into modules containing tube steel, have been in the public domain for some time. Also, sinisisolutions.com put the construction details of DuraBarrier online through photographs. DSBI has exhibited samples of DuraBarrier publicly at trade shows. DuraBarrier ceased being unique intellectual property in 1976, when the first test was run by Cape Durasteel Limited, whose test reports were disseminated worldwide through distribution networks and sales staff. As a result, there can be no serious claim by DSBI of having unique technology, intellectual property or scientific research and experimental development under the Income Tax Act of Canada. The A40 test is particularly deceptive in its use, with Promat UK as a co-conspirator in product misrepresentation, or unfair trade practice, through authoring the A40 test report, which does not explain the fiduciary ties between BFTC, Promat UK and DSBI in the test report, and cherry-picks its own pass-fail criteria, which is normally not necessary, as the standards have spelled out the conditions of acceptance, since it is used to claim 6 hours of fire resistance. 6 hours fire resistance would be impressive, if the product met the conditions of acceptance of ASTM E119, NFPA 251, CAN/ULC-S101 and/or UL263, which are all essentially identical. As a species, homo sapien does not currently possess the knowledge to meet the necessary conditions of acceptance at a thickness of 3/8” or 9.5mm. To believe otherwise, requires a solid lack of knowledge in the field of fire-resistance, where wall thicknesses of several inches are needed to provide sufficient strength and insulation to meet such conditions of acceptance. For example, DSBI’s V466 2-hour UL listed system is over 4 inches or 10 cm thick. DSBI’s V460 UL listed 4-hour wall is 6-3/4” or 17.1 cm thick – for 4 hours, but DuraBarrier, ineligible for UL listings, is only 3/8” or 9.5mm thick and is marketed for 6 hours of fire resistance. 4-1/2” for 2 hours, 6-3/4” for 4 hours, but only 3/8” for 6 hours?

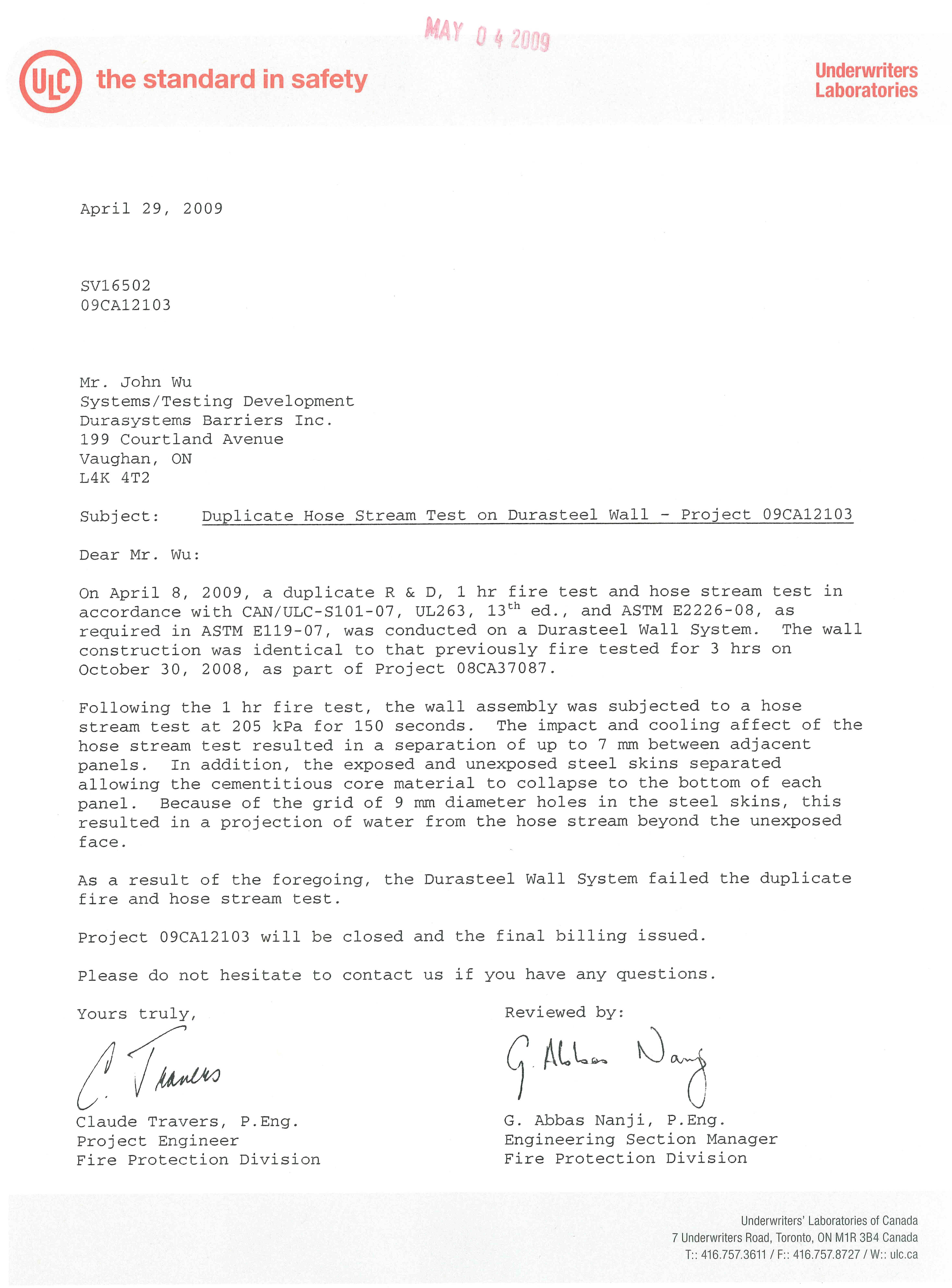

So, looking at Table 1.2.2 in test index 34, in tests A1 through A40, not a single hose stream test had been run, or run successfully, meaning any and all claims of fire resistance within North America, are completely deceptive. Then we get to test A41, which DSBI uses here, again, deceptively, to “Frankenstein” a hose-stream test onto the other non-compliant fire tests. Again, this is a purposeful deception and clear violation of Canada’s Competition Act and 15 US Code Paragraph 45. It is false advertising. In the first place, you cannot cherry-pick things you like from different tests and then cobble a rating together. It does not work that way. Secondly, Test report A41, signed by (now retired) Underwriters Laboratories of Canada engineers Claude Travers and Abbas Gulam Nanji, was not only a failure, and thus ineligible for listings, but it also violated test protocols in multiple ways, and, UL Canada clearly indicates the fallacies right inside of the report and indicates that DSBI are not to mention UL or that test in connection “with this wall system” (DuraBarrier). Table 1.2.2 calls it a “DuraBarrier Hose Stream Test”, AND mentions UL of Canada, contrary to UL’s explicit instructions, and thus expects people to use its result, to graft the hose stream test resistance onto other tests, where no hose stream test was performed. A41 and A42 were part of a series of tests following a DuraBarrier installation rumoured to be located at USNRC licensee TVA Watts Bar nuclear power station, which, supposedly, enquired about a missing hose stream test up until that point, prior to the 2008 and 2009 UL Canada test series. The UL Canada test series culminates in a single page letter report by UL Canada, dated 29. April 2009, by Claude Travers and Abbas Nanji to DSBI’s former staffer, Mr. John Wu. The letter informs DSBI’s Mr. Wu, that a 3-hour fire resistance test had been performed on 30 October 2008, as part of project 08CA37087. Following a 3-hour fire test, DuraBarrier failed the hose stream test. As soon as you see this, you need to realise that DSBI’s claim of 6 hours of fire resistance, which must include hose stream resistance, is false advertising and NFPA 850 compliance is out the window. Standards permit a re-test of an identical test sample, and only exposing this sample to a 1-hour fire endurance test, followed by the hose stream test, using the water cannon. If, beginning within 10 minutes of the end of the fire, it passes the hose stream test without through-projection of water to the unexposed side, then the sample is compliant from a hose stream perspective – if there are no other test standard violations, of which there are several, as Claude Travers and Abbas Nanji pointed out under separate cover. One small problem: the report indicates that following the 1-hour fire endurance test of DuraBarrier on 08. April 2009, DuraBarrier FAILED the mandatory hose stream test, without which there can be no claims of fire resistance in North America or per NFPA 850 for transformer fire walls. Indicatively, this particular single UL Canada page report does NOT show up in Table 1.2.2 of DSBI test index 34. DSBI may claim violation of proprietary information, but, in fact, it proves its culpability in false advertising, and thus, the defrauding of DuraBarrier customers and ratepayers, whose financial damages of this fraud go beyond the invoiced amount DSBI received per sale of DuraBarrier (station shut-down, installation, sinisisolutions.com as a middle man, or the previous cut-out – CSSI, plus local vetting for seismic and wind by a locally licensed structural engineer). This is where we get back to test A41, which is completely rigged. Here are the fallacies in the A41 test, as reported by UL of Canada: The test sample size was too small, at 9.09 square metres or 97.85 square feet, well below the minimum of 9.3 square metres or 100 square feet. Right there, the whole test is irrelevant, on size alone – again. But it does not stop there. Thermal failure occurred within only 17 minutes of the start of the test. After that point in time, there is no point in continuing, especially whilst claiming compliance with NFPA 850, which recommends that test samples comply with all conditions of acceptance of ASTM E119 or UL 263, which are both identical with CAN/ULC-S101 and NFPA 251.

It gets worse.

The test sample was not solidly fastened all around the restraint frame, which is a standard requirement, thus permitting expansion without negative effect upon the test sample.

It gets worse.

Where there were gaps, on the sides, between “DuraBarrier” and the restraint frame, these gaps were filled with ceramic fibre furnace insulation.

It gets worse.

The whole test sample was flashed with 22 gauge or 0.85mm galvanised sheet metal. Paragraph 5 of ASTM E119 indicates that it is required for test samples to match installed configurations. Flashing one’s test sample with sheet metal, after proving conclusively that the hose stream goes through unflashed DuraBarrier, when the installed configurations in the field are not flashed with sheet metal, when trade show samples, printed and online literature show no sheet metal flashing, is called cheating. No wonder UL Canada warned against the use of the UL name in connection with “this wall system”. The test sample was too small, not fastened all around the restraint frame so it could expand without penalty, the temperature failed in about a quarter of an hour. Yet DSBI mentions the UL Canada test report as a “DuraBarrier Hose Stream Test”. There is no stand-alone hose stream test. It only forms part of other test procedures. To show this rigged and failed test, ineligible for UL listings, together with other tests where either no hose stream test was run, or where it failed, is clearly false advertising.

Then we get to test A42. True to pattern, the test sample size was below requirements also, clocking in at 9.03 square metres or 97.2 square feet, meaning it is completely irrelevant on size alone. Thermal failure occurred this time in only 10 minutes, meaning it was irrelevant from that point in time on, even if it did not have other fallacies, which it does. The report does not mention the use of a hose stream test, without which, it is meaningless for wall systems in North America, especially in connection with claims of meeting the recommendations in NFPA 850. To buy some insurance, table 1.2.2 tags the A42 test as “special services test to ASTM E119 temperature curve”. Canada’s Competition Act is quite clear that false impressions rendered are illegal, even by the exact letter, it may not seem like a direct lie.

Let’s skip to the bottom of the table, Test A59. Pictures of this outdoor test at Lambton College, are shown on durasystems.com as well as by sinisisolutions.com. DSBI calls this a “DuraBarrier SF (small footprint) 4-hour Hydrocarbon Test.

In North America, hydrocarbon fire testing means compliance with UL1709 (see standardscatalog.ul.com/standards/en/standard_1709), whose heating regime can be seen here: commons.wikimedia.org/wiki/File:Din_iso_astm_ul_curves.JPG. Internationally, there are also other Hydrocarbon time/temperature curves, shown here:

commons.wikimedia.org/wiki/File:Tunnel_hc_iso_curves.jpg. All have a very rapid heat rise and require the use of a calibrated furnace, also with defined furnace pressure during the test. In North America, and in exterior use around the world, the premier standard for fireproofing in refineries and offshore platforms, is UL 1709, (This is apt here, as transformers are filled with oil.) which also uses shielded thermocouples, whose input governs gas supply into the furnace, in order to maintain the necessary heating regime, and furnace pressure, within defined tolerances. It is not possible to achieve this in an outdoor test. By inference, a hydrocarbon fire qualified wall necessarily means a wall test run to ASTM E119, with the substitution of the use of the UL 1709 time/temperature curve. By the use of the defined terminology (fire resistance for a wall and hydrocarbon), particularly in connection with the claim to “meet the stringent requirements of NFPA 850”, which actually has no requirements, since it is a recommended practice, as opposed to a test standard with mandatory language, DSBI wittingly employs false advertising. It is known from UL Canada’s 1-page letter report, which confirms that DuraBarrier failed the hose stream test after only 1 hour of ASTM E119 or CAN/ULC-S101 fire endurance, that 4 hours of hydrocarbon would not result in DuraBarrier’s resistance to a hose stream test, which is implied to be included with the use of the terminology DSBI uses. Lambton College states that at the end of the A59 fire test, DSBI donated the wall for fire service training, which indicates the wall had significant strength left, which is not possible given an UL1709 compliant fire exposure, if it fails a hose stream test after only one hour of the lesser E119 fire endurance testing. If the wall can handle fire service training after the fire exposure by Lambton College, one must wonder how much of the fire or heat actually landed on the test sample and whether, perhaps, the wall was flashed, like the A41 test sample, which has nothing to do with how DuraBarrier is sold and advertised, where no flashing is shown, without which it cannot hold a hose stream test after only 1 hour. Even with the flashing, the sample was noncompliant. Also, NFPA 850 mentions the necessity for transformer fire walls to be able to handle fire event fragmentation from exploding bushings and lightning arresters – which produce ceramic shards. If a DuraBarrier fire test sample cannot hold a hose stream test after only 1 hour of an E119 fire, how is this barrier expected to prevent damage from flying shards, sent aloft by explosions, during a fire? YouTube videos of large transformer fires and explosions routinely show fires to burn for a while before an explosion, thus lending at least anecdotal evidence to the recommendation in NFPA 850 for transformer fire walls to be valid.

Now, let’s skip back up table 1.2.2 to test A43. A43 is credited to LKD Technologies, and Mr. Ken Evans. In the back of the test index, LKD is shown as being in Canada. Canada has a lot of real estate, but LKD and Ken Evans appear to be of no fixed address, unless accurate contact information was purposely edited out by DSBI before filing the reports. The URL lkdtechnologies.com does not exist and neither does the e-mail address of kevans@lkdtechnologies.com. A43 is called a blast and ballistic test. Neither company nor individual can be found online. There is no accreditation for testing or certification on record with Standards Council of Canada for LKD. LKD, of no fixed address, is listed by DSBI as an “independent test laboratory”. The test report has extreme disclaimers, discouraging the use of the report. The report shows test samples made of as many as four layers of Durasteel, with and without sand fill. This would be far more elaborate and costly than a single sheet DuraBarrier installation. Results are listed as “theoretical”. There is no record of the location of the test or equipment calibration, or sign-off by a ballistics technician. No actual test records or results are in evidence. The only thing resembling DuraBarrier, is “Test 1” on page 22. It fails “Levels 2 and 3a”. Without a proper test record, calibration and verifiable results, and without so much as an address, this report is more of a work of fiction than anything that would count towards establishing a fitness for purpose for anything at all. Yet it looks attractive, as a line item in table 1.2.2.

Test A44 – another beauty by Ken Evans of LKD Technologies, of no fixed address, presumably but not verifiably, in Canada. This one is called “Ballistic test, additional bulletproof material for DuraBarrier”. To begin with, there is no “bulletproof” material. Shoot at something long enough and with sufficient projectiles, and it will eventually break. The use of the term is, once again, false advertising. Also, paragraph 5 of ASTM E119 indicates that test samples must match the installed configuration, meaning that added armour must be included at the time of fire test, which did not happen here. No Durasteel was tested in A44. A44 mentions the ballistic test standard of NIJ, the National Institute of Justice, which is standard 0801.1. But mentioning the standard and lifting portions of it for the purpose of authoring A44, is but a deception. NIJ 0801.1 requires the use of a calibrated range and a distance between the end of the rifle and the test sample of 5 metres or 16.4 feet. Then, Mr. Ken Evans concludes that the armour plating used must maintain a distance to the end of the rifle, of minimum 100 metres or 328 feet. By comparison, a football field has a length of 91.44 metres or 100 yards. A44 provides no evidence of testing done, no ballistic technician sign-off, no test location. Just keep shooters 100 metres away for the armour plating to work, it concludes. Again, if one applies such armour plating to DuraBarrier, without incorporating it at the time of the fire test, then such fire test without the extra plating is null and void. There is no test range, with a receiver and chronometer, in compliance with NIJ 0801.1, at a distance in excess of 5 metres or 16.4 feet, making this entire exercise completely bogus.

Test A45. Again, this is done by one Ken Evans of LKD Technologies, somewhere in Canada. No address, no phone number, the e-mail address does not work. Importantly, A45 indicates that it is a DRAFT REPORT. It is not finished yet, since 18. December 2006. Unfinished work, listed as independent testing by someone who cannot be found in the public domain, of no fixed address. This time, table 1.2.2 calls it Blast Test, DuraSteel assemblies. Presumably the spelling of Durasteel with a capitalised S, is to get some differentiation from the original Durasteel, sold to DSBI by Promat UK. All tests by Mr. Ken Evans and LKD Technologies are listed as ad hoc. It is not necessary to do ad hoc testing where accredited national standards exist, unless one is testing a novel concept or idea, typically something in excess of existing requirements. There are ballistic and explosion/fragmentation standards is existence, making the use of ad hoc testing quite unnecessary – unless, as is the case here, one attempts to lower the bar whilst mentioning the standard number to make it look good. Again, in A45, samples with multiple layers of Durasteel are mentioned, which is far from the single Durasteel sheet, unflashed DuraBarrier that DSBI and sinisisolutions.com promote. Again, Mr. Evans describes test samples consisting of multiple layers of Durasteel, with and without sand fill. Mr. Evans muses about blast resisting rooms, made of these Durasteel walls, whereby it is not clear what such rooms would be for, and where the blast might come from. Is the room supposed to keep contents or occupants safe from an external blast or the other way around? And why not build such rooms of concrete, which is much cheaper and readily available the world over, than several layers of Durasteel with or without sand fill? There is no actual testing in evidence in the report. No test location, technician sign-off, equipment calibration, nothing. The whole things appears to be a theoretical exercise, and unfinished, since it is evidently a draft.

A46: This is another draft report by Ken Evans of LKD Technologies, of no fixed address, presumably somewhere in Canada. Again, this draft report vaguely describes blast resistant rooms involving walls made of multiple layers of Durasteel, which is not inexpensive. The only thing in evidence in terms or any actual test work having been done, is test work by the predecessor manufacturer of Durasteel, namely Cape Durasteel Limited, 3 years earlier. If the manufacturer, before the acquisition of its assets by Etex Group of Belgium, which owns Promat, ran in-house testing favourable in outcome, then this is but indicative in advance of third-party testing. The draft report concludes that such an imaginary multi-layer Durasteel room would not be able to withstand a 20 lbs or 9kg charge of TNT. So, A46 draft report’s conclusion is one of failure, but the testing is not in evidence. But if one does not have the test report and does not trouble oneself to look up the laboratory, then it makes table 1.2.2 look good. Blast test – DuraSteel rooms. Sounds good – until you read the back-up. This type of thing is exactly what is meant in Canada’s Competition Act, by providing a false impression – in this case, using a lab and engineer of no fixed address, in the form of a heavily indemnified confidential draft report.

A47 – This is listed in table 1.2.2 as a sound absorption test by Vibro Acoustics, which is a properly accredited test facility with a decent report – practically refreshing after all the malarkey above in table 1.2.2. There is only one problem. It is DuraBarrier, suitably insulated with fibreglass insulation, available at common building supply retailers the world over, but it does not identify the density of the fibreglass, which is the “active ingredient” in the test. Without knowing the density, the maker can substitute ANYTHING and claim it was as tested. Vibro Acoustics is not accredited for certification. Therefore, this is but a test report. To insulate DuraBarrier, without incorporating it at the time of the fire test violates paragraph 5 of ASTM E119, meaning that fire behaviour as a result of the added insulation is unknown, which means, even if DuraBarrier testing did meet the conditions of acceptance of ASTM E119, which is most certainly does not, then this test and any installations resulting from it are completely meaningless. It was also not necessary to do this test, for sound absorption, since one can simply look up the sound absorption performance of common insulations. By not identifying the active ingredient inside of the test report, this test is essentially useless, except to enable DSBI to engage in secrecy over a really standard building supply material. By not testing the added components over and above what is known as DuraBarrier to ASTM E119, in compliance particularly with E119’s paragraph 5, A47 provides no extra value – but the mere mention of it in table 1.2.2 looks good, unless one reads and understands the back-up and the test standards.

A48 – This is listed in table 1.2.2 as a DuraBarrier sound transmission loss test, by a proper lab, Architectural Testing, now Intertek, in York, PA. Intertek is accredited by SCC and ANSI both for testing and certification. The A48 test, however, was not intended for certification purposes, meaning that its components were not verified to be under follow up service by the laboratory, and meaning that it is not eligible for certification listings. It is simply a fee-for-service test. This time, 4 inches or 10 cm of rockwool, again of undisclosed density, were added to DuraBarrier, as the active ingredient. Identically to A47, without having the report indicate the density, the report is essentially meaningless, because the end-user would have to rely on the vendor to use the same material as what was tested, which was not verified by the laboratory, since the test was not run for the purpose of obtaining a certification listing. Identically to A47, it is unnecessary to run such testing, because all insulation manufacturers can provide sound absorption data on request. Identically to A47, the whole thing violates paragraph 5 of ASTM E119. Fire test samples must match the installed configurations. As soon as anything is added on or removed, one must then test altered configuration that to obtain new test results. Without that, we have, again, false advertising.

DSBI call themselves experts. Therefore, all the fallacies in the test described in table 1.2.2 of test index 34 are necessarily known to DSBI. It is unclear the extent to which sinisisolutions.com is, or is not aware of these test fallacies. However, Mr. John P. Sinisi is listed by NERC as an instructor on two web pages, he shows a falsified Bosik ballistic test report and calls the A59 Lambton College “test” by DSBI a jetfire test. Jetfire testing is essentially a large flamethrower test, available from Intertek and Southwest Research, in San Antonio, Texas. DSBI makes no mention of Jetfire testing in Table 1.2.2 of test index 34. Sinisi also writes on his website that DuraBarrier is made in the USA. That is definitely not the case and he ought reasonably to know better whilst acting as a distributor for DSBI.

This report was posted on Ripoff Report on 10/24/2018 03:47 PM and is a permanent record located here: https://www.ripoffreport.com/reports/durasystems-barriers-inc/vaughan-ontario-l4k-4t2/durasystems-barriers-inc-dsbi-durabarrier-high-voltage-transformer-fire-barrier-is-a-sca-1465535. The posting time indicated is Arizona local time. Arizona does not observe daylight savings so the post time may be Mountain or Pacific depending on the time of year. Ripoff Report has an exclusive license to this report. It may not be copied without the written permission of Ripoff Report. READ: Foreign websites steal our content

If you would like to see more Rip-off Reports on this company/individual, search here:

#1 Author of original report

Private sector takes civil actions against John P. Sinisi and DuraSystems Barriers Inc. (DSBI).

AUTHOR: Whistle - (United States)

SUBMITTED: Friday, November 16, 2018

Recent private sector activity, since the publication of this ripoff report has taken some chunks out of the lies of both durasystems.com and sinisisolutions.com or firebarrierexperts.com. Let’s start with a useful organisation: NERC. NERC stands for North American Electric Reliability Corporation, which is described here:

https://en.wikipedia.org/wiki/North_American_Electric_Reliability_Corporation

It would appear that one party one had better not mess with is Underwriters Laboratories (UL):

https://en.wikipedia.org/wiki/UL_(safety_organization) ,

as well as its Canadian daughter company, Underwriters Laboratories of Canada (ULC):

If you read the post above, you will note that central to the scam by DSBI, is the A41 test at ULC, which was both rigged and failed, AND it contained an unmistakable statement by the author of the report, (now retired) ULC engineer Claude Travers, as well as his reviewer, Mr. Abbas Gulam Nanji, both experienced fire-resistance engineers, with decades working in the business of qualifying products for UL classification and thus code compliance, saying that DSBI cannot mention ULC in connection with “the product or system” (DuraBarrier – as in single sheets of Durasteel fastened with sheet metal screws to a steel frame, the subject of tests A1 through A40 plus, most recently, A59). Contrary to this ULC directive, DSBI’s test index 34, Page 6, Table 1.2.2, mentions A41 as a ULC test and calls it “DuraBarrier hose stream test”, run at ULC. That is a blatant lie, since DuraBarrier is not shown, advertised or installed with the extra sheet metal flashing, without which, ULC proved that the hose stream fails both after 3 hours and, after only 1 hour of fire exposure to the ASTM E119 time/temperature curve.

John P. Sinisi “taught” 2 “courses in ballistic fire barriers at NERC meetings of member utility companies.

The presentations by John P. Sinisi, during those NERC events, were posted on NERC’s website, at the following URLs:

If you click on those URLs, you will find that those presentations are now gone.

Further, DSBI used to post its test index 34 at the following URL:

http://www.durasystems.com/downloads

That page had a hyperlink, which led to the PDF file containing test index 34 and its predecessors. Now, it says “Test Index 35”. But when you click on the hyperlink for Test Index 35, what happens, as of November 16th, 2018, is that another tab opens in the browser, which contains the same page that you started from, which is http://www.durasystems.com/downloads.

Also, the various web pages of Mr. John P. Sinisi, have been cleansed of inappropriate references to Underwriters Laboratories. John P. Sinisi, in the public domain, meaning with the knowledge of the world at large, including DSBI, went significantly further in claims concerning the effectiveness of DuraBarrier than DSBI did. Sinisi actually claimed 4 hours of Jet Fire testing, done by UL, on the basis of the A59 outdoor Lambton College test. DSBI mentions it as a 4- hour hydrocarbon test, which is deceptive enough. But to convert it into a jet fire test, which is a large and very severe flamethrower test:

https://www.youtube.com/watch?v=fE8Xz-1mmdk

which UL does not even offer, is taking the deceptions to a new level. The photographs on Sinisis’s old sites clearly show the same A59 test shown on DSBI’s site, but also include an image of a consultant, who attended and praised the test on Lambton College’s site, which is inexplicable.

Sinisi describes himself as a 30-year fire barrier expert. This indicates that the deceptions are not errors.

Another obvious deception is in one of the PDF files NERC recently removed. The PDF contains an altered image of a test report by Bosik Technologies 2013 Limited:

Bosik is a perfectly legitimate firm that performs ballistic testing in Ottawa, Ontario, Canada. One of the NERC PDF files by Sinisi, contains a copy of an altered Bosik test report. Sinisi removed the Bosik logo and replaced it with his own logo. To the right side of his logo, on the top, Sinisi writes that the test was run at a “third party test lab certified in UL 752 ballistic test procedures”. This is classic Sinisi. There is no such thing as a “certified” ballistic test laboratory. Test laboratories may be “accredited”. In this case, accreditation for testing, certification and standards writing, are issued, in Canada, by the Standards Council of Canada:

https://en.wikipedia.org/wiki/Standards_Council_of_Canada

Bosik makes no claim to being SCC accredited, nor does it show up in the list of laboratories accredited in Canada for testing, certification or standards writing. And why would Sinisi superimpose his logo on top of a Bosik report? Look at the bottom of the report. Normally, test reports are signed by the ballistic technician, meaning a qualified individual with training, as well as a reviewer. Sinisi wiped out the name of the Bosik ballistic technician and put in his own name. As the reviewer, he put in his wife’s name, using her maiden name.

If either of the two Sinisis were ballistic technicians, they would be capable of running a test range, such as the one shown here:

https://www.youtube.com/watch?v=p25atlCeIXc

The question begs, in the event of the falsified Bosik test report, if, as Sinisi writes, at the top right-hand side of the document, the lab were something OTHER than Sinisi’s own facility, then why would such a “certified” (by WHOM?) facility let Sinisi and his wife come in to run the kind of equipment shown in a laboratory, such as the one in the above YouTube video? Can you imagine owning and operating a laboratory, for a living, and then letting the “30-year expert” and his wife come in and run the equipment instead of your own technicians? That is absolutely crazy, and in the public domain, which means that DSBI was also aware of these claims – made for years online and in presentations.

Further, to the left-hand side of the falsified Bosik ballistic test report, Sinisi claims 5 consecutive shots in the same spot. If that were true, it would actually be a violation of UL 752, which requires a shot pattern, such as is visible in the above YouTube video. 30-year expert!

The lesson here, is that what began as one set of deceptions in the A40 test report in England, then snow-balled into all the deceptions by DSBI and then into a mountain of deceptions by Sinisi.

Everything depends on an absence of an Authority Having Jurisdiction, which would be accustomed to going through certification listings and test reports and comparing those against standards and codes to determine fitness for purpose. DSBI’s sales tool is clearly the test index (now banished from its website), quite possibly in the hope that customers would not request copies of the test reports, and/or that such test reports might be sent and then filed by customers as “received”, but not read or understood, let alone compared to the standard test requirements and conditions of acceptance. “Less is more”. Depending on ignorance of customers who do not have the benefit of an AHJ for outdoor substations, whilst making outlandish claims, left un-investigated by customers, adds up to lucrative sales for the perpetrators, whose costs, including substation shut-down, procurement, engineering, shipping, installation, were passed on to ratepayers in North America, for the purpose of critical infrastructure protection:

https://www.dhs.gov/what-critical-infrastructure

under the false guise of 6 hours fire resistance and compliance with NFPA 850’s “stringent requirements”. CAVEAT EMPTOR!

Advertisers above have met our

strict standards for business conduct.